Hydraulic Cylinders

We have four ranges of hydraulic cylinder – the C10 standard industrial cylinders; CEPAC and CEPAC plus cylinders for subsea and hostile environments; and PENCYL stainless steel cylinders for bore sizes from 10mm. We also offer a full cylinder refurbishment service.

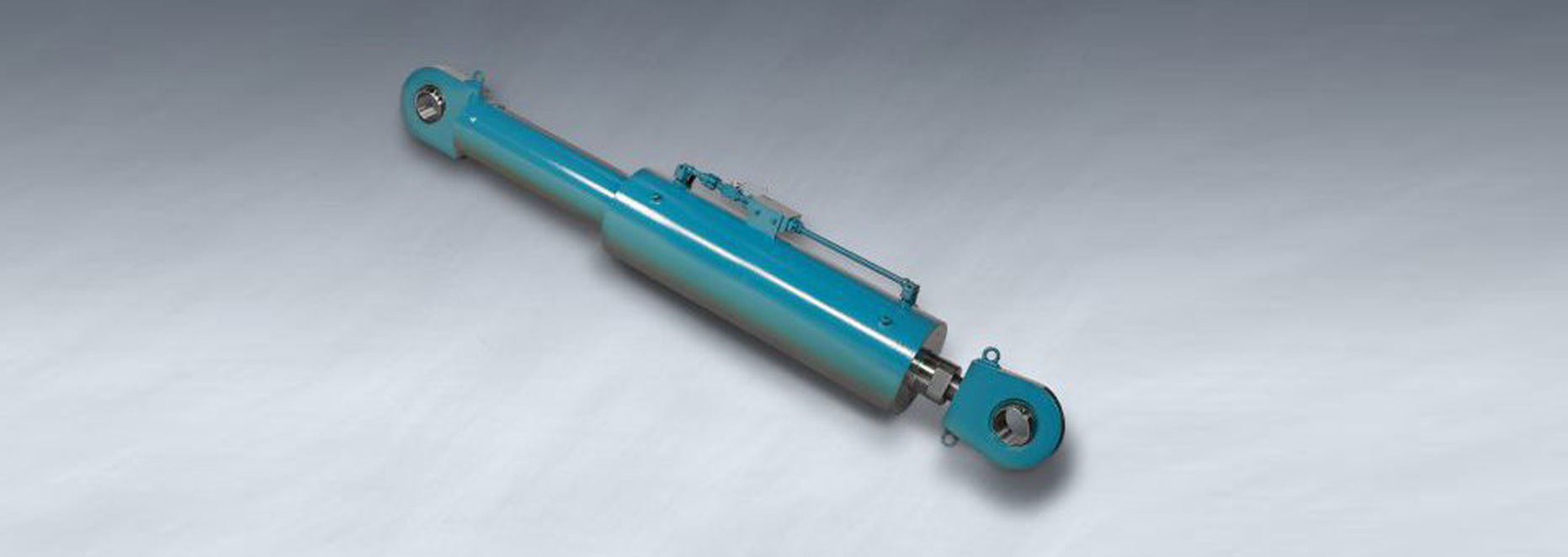

CEPAC ®

Widely used in the material-handling industry, and ideally suited to most general engineering duties, this comprehensive range offers a perfect combination of quality, reliability, and cost-effectiveness.

Working pressure 250 bar

Test pressure 350 bar

431S29-‘T’ Stainless Steel, hard chrome plated rod

Honed DOM/ST52.3/EN10305 E355 Steel tube

Internal linear transducer option available

Custom cylinders now up to 450mm bore

Client applications include, launch and recovery systems (LARs), walk to work gangway, reel drive systems (RDS), ship cargo ramps and wind turbine piling.

Walk to work

LARS

CEPAC ® Plus

Deployed across the world in lifting frames, emergency pipeline repair systems, tensioners and other civil applications, our CEPAC Plus range of larger cylinders are available up to 450mm bore.

To find out more, and to learn about our 3-D Step files, contact our Engineering Department.

PENCYL ® Stainless steel cylinders

Our exclusive range of 316 stainless steel cylinders with bore sizes of 10, 16, 20 and 25mm is used in the nuclear, offshore, food and chemical industries, guaranteeing high performance in remote and corrosive environments.

Mounting styles as C10 and CEPAC ranges

Working pressure 350 bar

Wide range of system fluids including fresh water

Client applications include, remotely operated vehicles (ROVs), bottling plant, water treatment.

ROV

C10 Industrial cylinders

Widely used in the material-handling industry, and ideally suited to most general engineering duties, this comprehensive range offers a perfect combination of quality, reliability, and cost-effectiveness.

Working pressure 250 bar

Test pressure 350 bar

20MnV6 hard chrome plated rod

Honed DOM/ST52.3/EN10305 E355

Internal linear transducer option

Custom cylinders up to 450mm bore

Client applications include: wind towers, fire trucks, tippers, cranes and biomass handling.

Wind tower

Fire truck

Cylinder refurbishment

APH offers a high-quality cylinder refurbishment and repair service. We strip down cylinders and examine the components before providing an accurate quotation for the work needed. All repairs include final assembly and test.

We ask for a PO to cover the cost of strip-down and assessment, which will be deducted from the final cost of any refurbishment or disposal. We also request any quotation for repair and refurbishment is taken up within 90 days, after which the units can be returned or disposed of as required.

Working pressure 250 bar

Test pressure 350 bar

20MnV6 hard chrome plated rod

Honed DOM/ST52.3/EN10305 E355

Internal linear transducer option available

Custom cylinders now up to 450mm bore

We offer a high-quality refurbishment and repair service for APH and

non-APH design.